Plastic to Oil

£1,8000,000

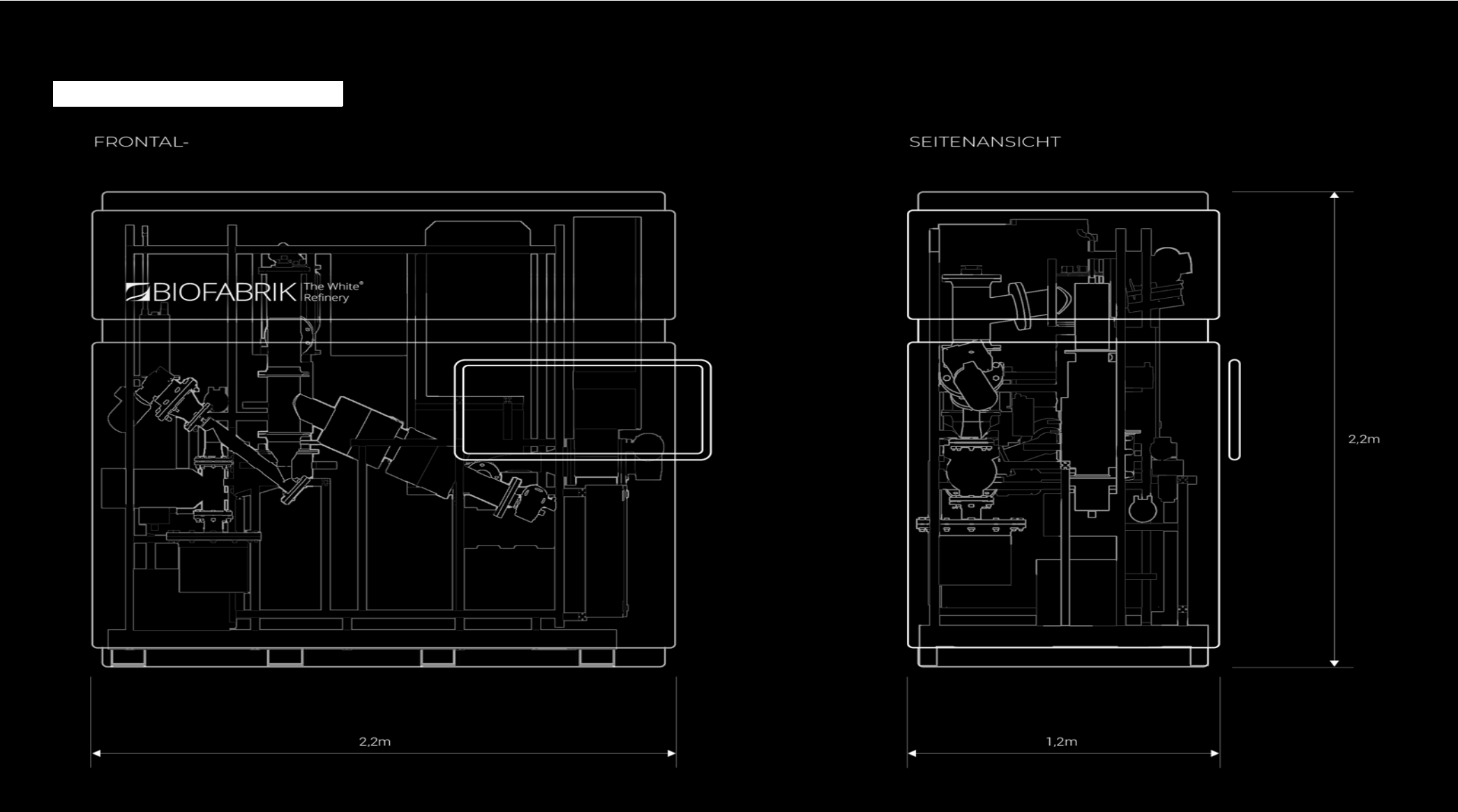

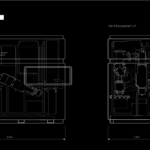

Size of the Container:

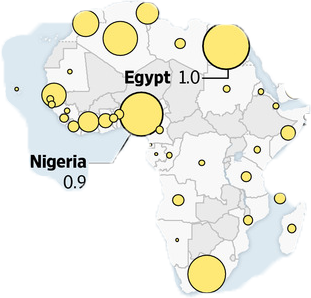

ECO VERIDI have West African distribution rights for a German manufactured plastic recycling technology/ on- site product. ECO VERIDI believes that there is a compelling investment case to locate a recycling machine (P5000) with a payback of approximately 3 years on an investment of £1.8m.

This note sets out further background to and details of ECO VERIDI’s proposal. For further details visit contact us page and sign up for your interest in the P5000

The machine has passed validation and testing in the UK, and a working demo is now in Dover, England. A demonstration of the machine can be arranged in Germany any time from now or a visit to our partners (QMRE) UK test site in Dover can also be arranged. Potential buyers can view this machine working in Burkina Faso West Africa towards the end of the second quarter of 2021.

BACKGROUND TO ECO VERIDI, BIOFABRIK & PYROLYSIS

Eco Veridi Ltd is focused on helping West African businesses to address their plastic waste pollution problem. ECO VERIDI is run and owned by Daniel Gallimore, Samantha Dempster and Sean Deane of whom have extensive experience in the construction and energy as well as project managing large, multi-site industrial/commercial developments.

ECO VERIDI has been pursuing companies that can help in decreasing the amount of plastic currently in Africa, India, and China. In the search for such companies’ pyrolysis, a thermal process where no flame is created and that reverses the process of making plastic (depolymerisation) was found to be an available solution. However, our research showed that many of the machines made used batch design and were too large to be deployed local to regions around Africa, India and China.

ECO VERIDI’s director Sean Deane met with Tim StClair CEO of QMRE in May 2020 to discuss a new product which he has exclusive rights for sale in UK. After seeing the product Sean decided to take the trip to Dresden, Germany to see Oliver the CEO of BIOFABRIK. After seeing the demonstration in Germany, it was clear the P5000 machine was a viable solution for ECO VERIDI’s African market.

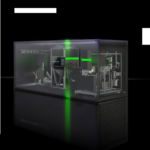

Following extensive research, ECO VERIDI signed an distribution agreement with Biofabrik. Biofabrik was chosen by ECO VERIDI because, unlike its competitors, it didn’t use burners to heat the thermal process and created a self-sustainable containerised plant that only required one hours of electricity to give continuous usage 24 hours, which is vital for African and Indian regions.

Biofabrik is a design company that owns the IP to the technology and has manufacturing capabilities through its relationship via industrial partner Nurmont – a mechanical engineering company established in 1985 with an excellent reputation and owned by Baumuller Group. Biofabrik have taken 8 years developing this system which has been extensively tested by Schur the world’s oldest packaging company.

INFORMATION ON BIOFABRIK’S P5000 MACHINE & INSTALLATION

The P5000 machine is the only available compact, electronically-powered pyrolysis plant available in the world. The machine can process 5 tonnes per day which, based on plastic polyolefins waste volumes.

The P5000 machine does not need planning permission given its size and is easily installed on site with minimal set up costs.

We can confirm that BIOFABRIK have commenced production on multiple orders received from their partners in UK, USA, Germany, UAE and Switzerland, including an international plastic producer.

BENEFITS OF USING THE P5000 MACHINE

By reducing the movement of plastic waste customers will reduce their carbon footprint by reducing plastic waste movement. Condensing waste plastic into oil is more efficient than bulk waste, landfill, incineration or export – all of which are disappearing as options.

Based on waste data, the waste managed by the machine is expected to deliver an attractive financial return, with income from two sources:

- Output material sales at an assumed £360 per tonne from the sale of oil, which ECO VERIDI will manage; and

- Packaging Recovery Notes (PRNs) at assumed £250 per tonne which are government incentives to recycle packaging. ECO VERIDI are currently in discussions with the Environment Agency (EA) to provide evidence and approve the qualifying of the oil for Packaging Recovery N

We estimate a pay back period of c. 3 years from an initial investment of machine cost £1.681m + site set up costs subject to survey. An optional reduction in Capex of £0.4m if customers wish to take up the Partner Model option with shared revenue, with a payback of approximately 2.2 years on an investment of c£1.35m which could prove an attractive alternative.

The operational cost include: Service £8k, Insurance 18k, Energy supply £32k Staff 43k Total £101k

We expect that capital allowances for early adopters of this technology will also be available but we have not factored these into our analysis so this could be further upside.

Given recent movements in oil prices, we have provided below a worst case sensitivity analysis for the material sales income and its impact on returns as well as historic oil prices over the last 5 years. This demonstrated that even based on an oil price significantly lower than historic there is still an attractive payback.

| Oil price ($pb) | $35 (Current price) | $28 (Assumed case) |

| Oil £ per tonne of waste | £268 | £215 |

| Output Material Sales income | £442,200 | £354,750 |

| P&L pa | £493,000 | £406,000 |

| Payback | 3.4 | 4.1 |

In addition, there is likely to be an option in the near future to extend the machine which changes oil to electricity and provide Islip with an electricity supply and provide significant additional financial and environmental benefits.

TIMELINES

- Delivery of test machine in UK: Projected December 2020

- UK Test machine demonstration: Projected September 2020 (Dresden April 2020)

- P5000 product testing complete: Projected January 2020

- Projected Approvals: Projected local authority licences expected to be received in November 2020

- Delivery of P5000: Projected December 2020 (assuming order placed in April 2020)

DETAILS ON THE CONTRACT

- Quotes available: Standard Purchase Model or Price Supported Partner Purchase

- Warranties: 1 year guarantee included in price (this is extendable yearly for an extra cost with an overall 10 year warranty)

- Servicing arrangements: The first two services at 6 months and 12 months are included – ECO VERIDI’s contract with Biofabrik stipulates that an engineer must be on site within 12 hours of any breakdown. Maintenance is between cycles estimated at 30 day intervals, training is

- Contract: The guarantee and contract are written into the appended

- Deposit Insurance: Third party insurance cover is provided on UK deposits.

- Manufacturer additional breakdown and business interruption insurance,

- Leasing: option available by

- Payment structure: A 50% deposit is required on placement of order. 30% is due once the machine is shipped, 20% is due once machine is commissioned and